I finally got some wood, but it wasn't from the order I've been awaiting for two months. I ordered it from International Violin in Baltimore. It's a great company: good products, decent prices, and man are they fast! Usually I get shipments from them one or two days after I order them . Left to right: spruce for the top, maple for the sides, neck and back. The pieces for the top and the back are split down the middle so they will open like a book, giving mirror-image grain.

I had a setback with violin #1. I carefully fit the neck to the body a while back, then glued it up. But I only yesterday discovered that during the glueup (presumably) the neck shifted and is now at the wrong angle to the body. This after gluing on the back, installing the purfling, and trimming the edges! Now I have to take the neck off and reglue it at the correct angle. I guess I'll take the back off to make it easier. I put the label in the wrong spot anyway, so now I have an excuse to fix that also.

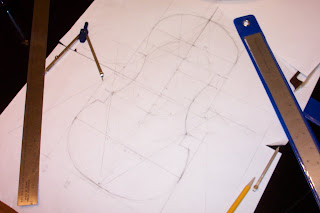

Anyway, this weekend I'll probably do the layout for the new form and cut it out if I have time.